ASTROSE® system

The inclination sensor is used in the ASTROSE® system. In the research project ASTROSE founded by the German Federal Ministry of Education and Research (BMBF) a basic concept of a monitoring system for high voltage power lines was developed. The system consisting of numerous sensor nodes measuring the inclination, the temperature and the line current of the spans of the high voltage power line. A single sensor node consists of a microcontroller, a real-time clock, an electronic energy management, a 2.4 GHz transceiver and the corresponding sensors. Equipped with two antennas and an additional antenna filter the components are housed in a cylindrical and conducting hull with a slot for easy mounting to the power line. The sensor node needs no battery. Instead the electrostatic fringing field of the high voltage power line is used as power source. The collected data is passed along the sensor chain and transmitted to a base station (Fig. 1).

This autonomous and energy self-sufficient sensor network is used to monitor the sag and therefore the safety distance of the power lines. Especially the increasing development of renewable energies as well as their fluctuating supply, particularly of wind and solar power let the distribution networks reaching their load limits. With the help of the ASTROSE® system the capacity utilization of the power lines can be optimized finally.

Further development and testing

With the end of the research project an extensive test run was started in September 2012 and is still running. The test takes place on a 110 kV power line near Chemnitz. For the necessary assembly works the power line could be easily turned off and on.

Together with Fraunhofer ENAS and Fraunhofer IZM, Microelectronic Packaging Dresden, KE Automation, envia NSG and MITNETZ STROM a lot of improvements were implemented during the year 2013. For example, a protection circuit has been added to protect the transceiver against high transients. These conditions occur when high voltage is switched on the power line as well as when environmental lightning strikes. Tests of the protection circuit in the laboratory showed that direct lightning discharges of more than 10 kV can be diverted successfully. In addition to other small improvements in the hardware, the software of the sensor nodes and the receiving station has been improved. The synchronization and data transfer among the nodes is more reliable and less susceptible to interference.

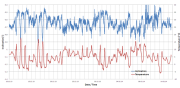

In parallel, the recorded data (inclination, temperature and current) were analyzed and compared with weather data of the test area and current load values of the power line. Figure 2 shows the typical correlation of temperature and inclination. Higher temperature leads to higher negative inclination, and it is to be seen that the inclination sensor resolves the fluctuation much faster than the temperature sensor that has a certain measurement delay due to its thermal capacitance and limited thermal conductance between the temperature sensor and the power cable.

|

|

Further information:

Contact

Dr. Steffen Kurth

Center for Microtechnologies

E-Mail:

steffen.kurth@…