Bulk micromachining

Bulk micromachining technologies have been under investigation at ZfM already since 1990. At this time, mainly anisotropic wet etching of Si was applied. For instance, a high precision acceleration sensor for airborne applications was developed within the "MIKROKIN" and "KINSENS" projects (1991-1997). The all-silicon bulk technology originated in Chemnitz has been transferred to LITEF GmbH in Freiburg. Nowadays the sensor (see Fig. 1) is fabricated in a small series and integrated in the Attitude and Heading Reference System LCR-93. It stands out by its high resolution (< 50 µg) and very low temperature drift (6 µg/°C) and offers a measurement range of 10 or 20 g.

By using bulk technology in combination with direct and anodic bonding, several devices have been developed and prototypes have been fabricated, such as:

- A micromechanical inclination sensor for measuring angles of 60° with a resolution better than 0.1° (glass-Si-glass compound), cooperation with GEMAC mbH

- A micro gyroscope for angular rate measurements (cooperation with LITEF GmbH)

- Several types of micro mirrors and micro mirror arrays for scanning and projection applications

- Two generations of pressure sensors for vacuum measurement, based on gas friction acting on a resonator. Hereby, the damping characteristics are changed depending on the pressure, and these changes are monitored capacitively

- Ultrasonic sensors based on membrane arrangements

Nowadays, several combinations of wet and dry silicon etching steps are available and allow a wider spectrum of 3D Si shapes and more precise as well as smaller components. Furthermore, the spectrum of bonding methods has been extended including eutectic, seal glass and adhesive bonding. Recent examples of devices fabricated with these advanced technologies are:

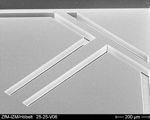

- Fabry-Pérot filters for the near- and mid infrared range (Cooperation with InfraTec GmbH Dresden) - a detail of a vertically deflecting spring is shown in Fig. 2

- RF MEMS such as high-Q varactors

For more details please see MEMS applications.

Figure 1 |

Figure 2 |

Contact

Prof. Dr. Karla Hiller

E-Mail: karla.hiller@…