High aspect ratio micromachining

ZfM has a long tradition in the field of High Aspect Ratio Micromachining. Several technologies have been investigated and verified using off-the-shelf wafers (SCREAM-like technology) or using SOI wafers (BDRIE technology). Furthermore, a new technology has been developed - called AIM (Airgap Insulation of Microstructures) technology. So up to now several MEMS prototypes have been fabricated by one of these technologies:

- The z-drive actuator for tunnelling microscopy with an out-of-plane deflection of few micrometers and a resonance frequency of about 40 kHz, the structure is suspended by two torsion springs

- A micromechanical scanning system with a high lateral deflection (about 20 µm) and high resolution within the nm-range

- Gyroscopes

- Various types of resonator systems: single resonators as acting or sensing devices, multiple band sensor arrays and wide band sensors for vibration monitoring

- On-chip integration (post CMOS) of a crystalline silicon MEMS oscillator device with a readout amplifier in standard CMOS

- Several types of accelerometers/inclinometers with varying sensitivity (0.5...15 g)

Despite the low fabrication effort required, AIM type devices are characterized by an outstanding signal to noise ratio and an excellent temperature stability. In combination with available analog ASICs a noise density of about 20...30 µg/Hz1/2 has been proven. Further reduction of noise density should be possible by ASIC optimization.

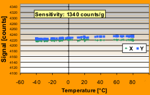

Several sensor types have been characterized with respect to their sensitivity change and offset drift vs. temperature. Exemplarily the zero g offset drift of a dual axis sensor AIM7E is shown in Fig. 2. As indicated a coefficient as low as 30 µg/K has been obtained. This is a value which can be achieved by other technologies usually only by temperature compensation.

For more details please see MEMS applications.

|

Figure 2 |

Contact

Dr. Danny Reuter

E-Mail:

danny.reuter@…