First project period 04/2006 - 09/2010

| Project No. | Project Name | Responsible |

|---|---|---|

| G4 | Precursor Synthesis for Advanced Interconnect Materials | Prof. Dr. Heinrich LANG |

Description

Chemical vapor deposition (CVD) can be used to produce metallic films for interconnect metallization in future generations of submicron integrated circuits. The advantage of the CVD technique, when compared with conventional PVD, is the high conformality of the deposited films and provides the ability to fill vias having small diameters as well as high aspect ratios.

Recently, copper(I) precursors were developed for copper film deposition, due to the low resistivity and superior electromigration resistance of copper [G5-1]. The most studied copper CVD precursor is (vtms)Cu(hfac) vtms = vinyltrimethylsilane, hfac = hexafluoro-acetylacetonate) [G5-2]. However, there is still a high potential for improving the properties of the precursor (volatility, high thermal stability, long-term storage etc.), and the film properties by using, for example, other, and hence better precursors or additives.

In contrast to the common usage of the CVD technique for processing of materials in industry, the basic knowledge of such a process is quite limited. Of interest would be to study the interplay of the copper precursor chemistry, gas phase and surface chemistry and chemical reaction engineering of CVD systems by interdisciplinary cooperations between natural scientists and engineers.

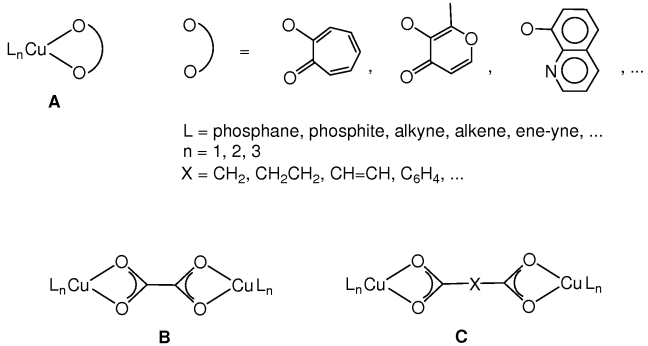

In this respect, in the proposed work new copper(I)- and partly copper(II)-CVD precursors will be developed, characterized and produced at the Institute of Inorganic Chemistry (Fig. 1).

Structural type B and C molecules are superior to type A species, because they should decompose in a straightforward manner by decarboxylation, elimination of n L to deliver elemental copper in quantitative yield. For structural type A molecules most probably a disproportionation is the favored decomposition. This is to be investigated during this project.

The preparation of type A – C molecules will be carried out in a 2-step synthesis protocol by the subsequent reaction of [CuX] (X = Br, ClO4, PF6, …) with M(O∩O), M(O2C-CO2) or M2(O2CXCO2) (M = Li, Na, …) and then with the respective Lewis-bases L.

Based on the experience gained from the systems described above, also other metal complexes will be synthesized. The newly developed metal(I) complexes will be tested as possible CVD precursors for the deposition on different substrates such as TiN coated oxidized silicon wafers in a cold and hot wall CVD reactor. The process parameters and their influence on film properties will be evaluated together with the Gessner group (G1).

|

|

Fig. 1: Selected copper(I) precursors to be synthesized. |

Film characterization will be carried out by the Hietschold and Zahn groups (G7, G8). Simulation of the deposition processes and modeling and simulation of the electrical and thermal behavior of nanoscaled interconnects will be done in collaboration with the groups of Otto (G2), Streiter (G3) and Ruan (F4).

Towards the synthesis of organometallic precursors, which can be used for the deposition of diffusion barriers, new high / low-k dielectrics and metal interconnects we will work together with Prof. Qu and Zhang.

References

| [G5-1] | For example: a) CVD of Nonmetals, Ed. W. S. Rees Jr., VCH (1996). b) The Chemistry of Metal CVD, Eds. T. Kodas, M. Hampden-Smith, VCH (1994) and refs. cited therein. c) P. Doppelt, Coord. Chem. Rev. 180 (1998) 1785. |

| [G5-2] | J. A. T. Norman, B. A. Muratore, P. N. Dyer, D. A. Roberts, A. K. Hochberg, J. Phys. IV, C2 (1991) 271. |