Technologies

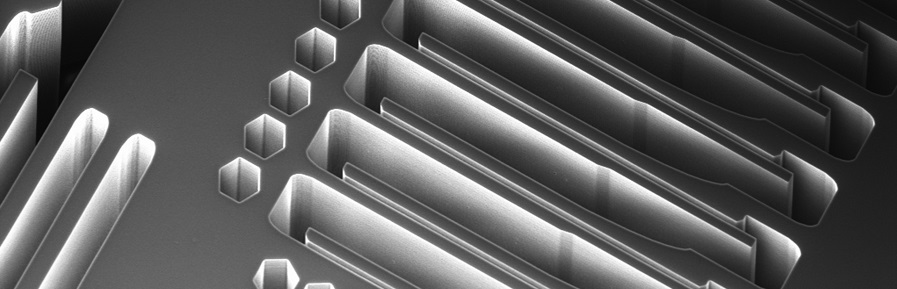

- High aspect ratio (HAR) technologies for high-precision capacitive MEMS: Airgap Insulation of Microstructures (AIM), Single Crystal Reactive Etching and Metallization (SCREAM), Bonding and Deep Reactive Ion Etching (BDRIE)

- Bulk technologies

- Piezo-MEMS technologies

- Thin film encapsulation

- MEMS packaging (0 and 1st level) and 3D integration

- Copper metallization (barrier, seed, fill)

- Low-k and ULK dielectrics (processes, integration)

- New materials and thin film processes

- Development and conceptual design of integration schemes

- Modeling and simulation of processes and equipment

- CNT-based interconnects

- Prototyping and assembling of (micro)fluidic systems

- Peripheral systems (instruments, electronics, software)

- Microfluidic systems based on silicon, glass, polymers, metals

- Liquid-based microfluidics

- (Bio)sensor integration

- Assay integration

- Integration of actuators (micro pumps, valves, heater)

- Gas-based microfluidics

- Gas-fluidic actuators (SJA / PJA) and transducers

- Prototyping and assembling of gas-based microfluidics for wind tunnel tests

- Nano lithography

- Electron beam lithography

- Nano imprint lithography

- Layer-based technologies

- Nanocomposites (semiconducting metal oxides, quantum dot-based layers)

- Magnetic field sensors (multi-dimensional GMR sensors, microstructuring, laser annealing)

- Memristive components (functional multilayers, circuit technologies)

- Packaging with thin, exothermic metal layers

- 1D technologies

- CNT functionality on wafer-level (coating, patterns, heterogenous integration)

- CNT material: type-selective CVD, material purification, assembly

- CNT-based piezoresistive sensor

- CNT-based FETs for sensors

- CNT-FETs for high-frequency applications

- Sheet- and web-based printing processes up to pilot scale (aerosol jet, inkjet, screen printing, gravure, dispensing)

- Printing of functional inks on flexible and rigid substrates with 2D and 3D surfaces

- Functionality formation by sintering of printed patterns

- Integration of printing technologies in manufacturing environments

- Design and printing-based manufacturing of tailor-made flexible thin film batteries

- Design, simulation, printing and characterization of customized antennas (RFID, WLAN, Bluetooth, LTE, UMTS,...)

-

Chemnitz University of Technology Ranks Third Again in StudyCheck.de's Ranking of Germany's Most Popular Universities

Chemnitz University of Technology receives a "StudyCheck Award 2024" and the "Top University 2024" certificate thanks to the very positive evaluations from its students and alumni – Additionally, Chemnitz University of Technology is the top state university in the live "Digital Readiness" ranking …

-

“Historical Treasures“ of the University Library are “uncovered“

From April 23 on, the University Library presents “book gems“ of its „Historical Collections“ within an exhibition and on the occasion of the TUCday at April 27, 2024 …

-

Chemnitz Physicists Travel to the 73rd Lindau Nobel Laureate Meeting

A celebration of scientific exchange: young scientists Maria Saladina and Fabian Samad will meet Physics Nobel Laureates in Lindau from June 30, 2024 onwards, and have the opportunity to network with other young scientists from around the world …

-

Europe-wide unique pilot project for a greenhouse gas-neutral circular economy is underway in Lusatia

The three Universities of Technology in Chemnitz, Dresden and Freiberg and the Zittau/Görlitz University of Applied Sciences signed the cooperation agreement for the joint establishment of the "Green Circular Economy" (CircEcon) research campus, which will receive over EUR 108M in funding …

-

TU Chemnitz TUCtag – 11th Alumni Meeting

Follow in old footsteps, meet former fellow students, teachers and colleagues and explore the …

-

TU Chemnitz Open Day

Discover your future, study in the European Capital of Culture 2025. No matter whether you are …

-

TU Chemnitz Game Night in the University Library

We would like to invite you to our game evening! Whether you're an expert at Monopoly or just fancy …

-

Career Service TUCconnect | Spring 2024

Get in contact with interesting regional and nationwide employers. You have the possibility to find …

-

TU Chemnitz Graduation Ceremony

The Graduation Celebration is one of the most beloved traditions at the TU Chemnitz. Brand new …

-

TU Chemnitz Enrolment Ceremony 2024/2025

New students are greeted each year at the beginning of the winter semester in a cherished …