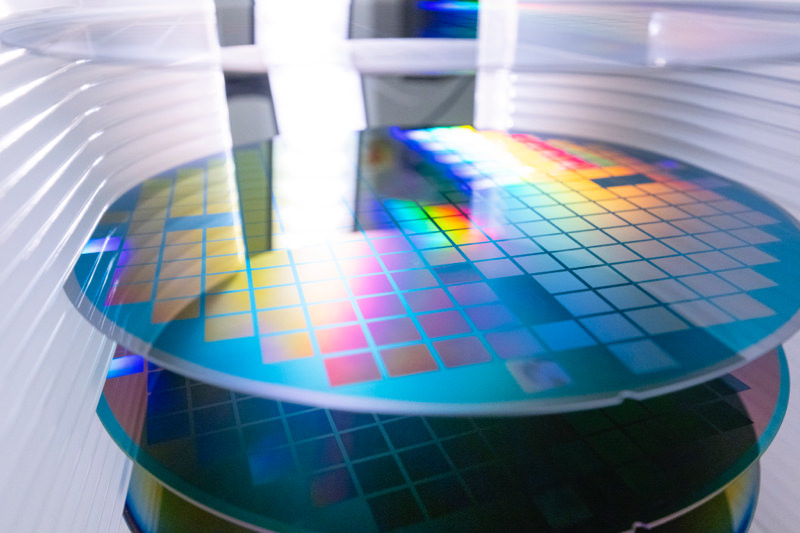

Innovative and sustainable semiconductor fabrication processes are the common goal

07.Nov.2024 Reseach News

The center for

micro- and nanotechnologies (ZfM) at Chemnitz university of technology coordinates

the recently started European project HaloFreeEtch to explore novel and

sustainable processes for semiconductor manufacturing. The project aims to

develop sustainable and halogen-free etching processes for the semiconductor

industry by reducing the use of halogene-containing chemicals and energy consumption.

Established semiconductor etching processes

rely on halogene-containing materials which pose significant environmental and

health risks. Thus, scientists from the ZfM will explore novel approaches to

etch silicon or glass by using hydrogen and innovative catalysts. Using such

environmentally friendly alternatives will reduce the ecological footprint of

the sector significantly.

At the ZfM, quantum chemical simulation methods

will be used to screen promising materials on the computer in front of lab

scale research to explore the process performance in the clean room environment

on state-of-the-art equipment. Together with the partners, novel methodologies

for sustainability-driven process development will be established. By combining

process- and sustainability models, the use of critical materials as well as

the consumption of energy will be tracked and optimized.

“For us it is very important, that the new

semiconductor processes are not only environmentally friendly, but also meet

the performance requirements of the modern semiconductor industry, leading the

industry into a more sustainable future.” says Dr. Jörg Schuster from Chemnitz

university, who is coordinating the European project.

Funded with about four million Euro from the EU, HaloFreeEtch will run for four years. The project consortium involves several leading European research and industry partners, among them the Fraunhofer Institute for Electronic Nano Systems (ENAS) in Chemnitz. The results are expected not only to revolutionize semiconductor manufacturing but also enable applications in areas such as microsensors and photonics.

More information on the project website https://halofreeetch.eu/

Contact: Dr. Jörg Schuster Technische Universität

Chemnitz, Email: joerg.schuster@zfm.tu-chemnitz.de