The Research Center

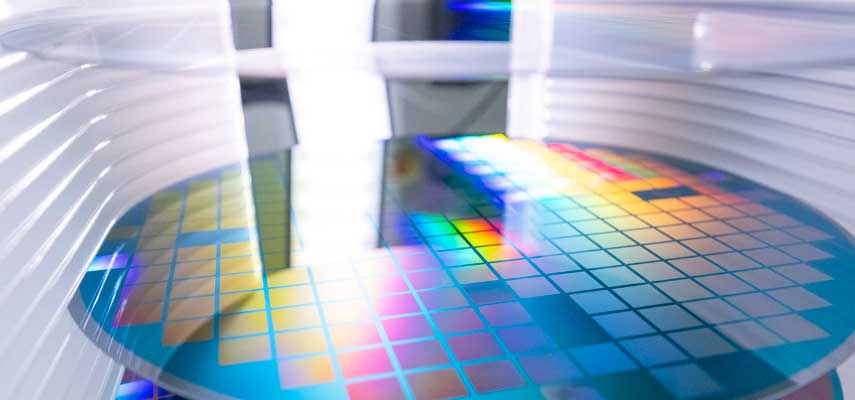

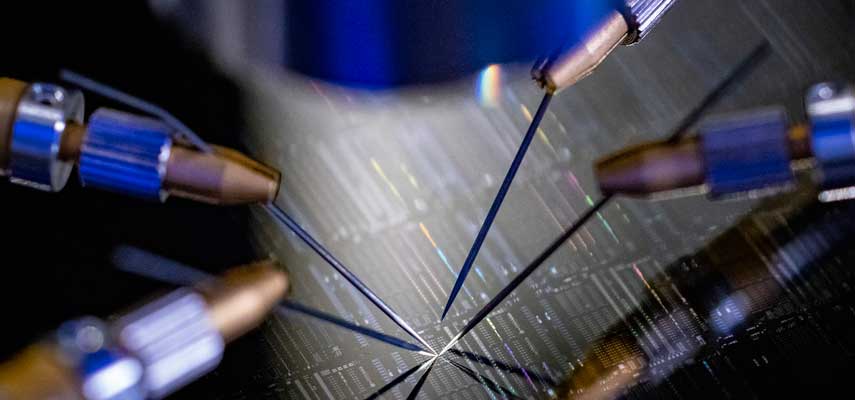

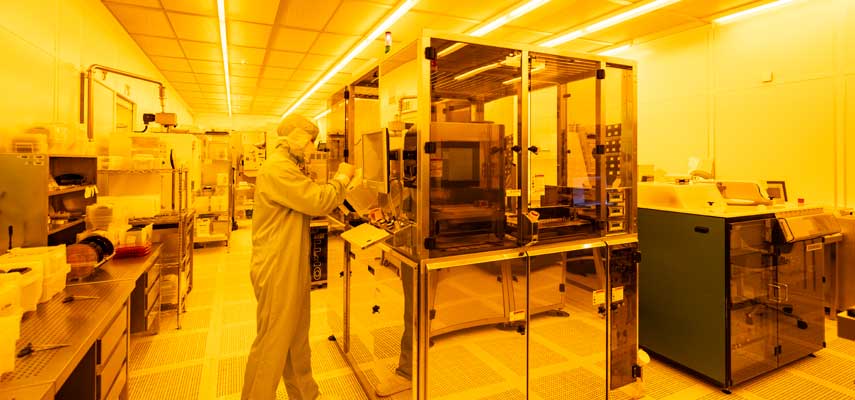

The ZfM is one of the world's leading research centers in the field of microsystems technology and nano technologies. The aim is research and development of new technologies for the micro and nanosystems of tomorrow.

The focus of the developments is set on miniaturization, energy requirements, performance and resource efficiency of micro and nanosystems. Together with partners from industry and research, we bring the developments into application.

ZfM at a Glance

Research News

Watch the 2nd webinar of the HaloFreeEtch project: Sustainability demands in Microelectronics: Innovations for a Greener Industry

After introducing the HaloFreeEtch project in our very successful first webinar, our second webinar focusses on the sustainability challenges in microelectronics. Two contributions from leading research institutions in Europe will highlight why we need to become more sustainable in electronics production.Read morePESM 2026: International Plasma Etch Workshop Moves to Grenoble – Call for Papers

Following the successful conference in Chemnitz in 2025, the Plasma Etch and Strip in Microtechnology (PESM) workshop series continues its journey across Europe. The 16th edition, PESM 2026, will take place in June 2026 in Grenoble, France.Read moreDDC Gold Award 2025 für das Konzept eines Ultraschallpflaster

Studierende der Hochschule für Gestaltung Schwäbisch Gmünd haben für ihr Projekt "Ultraview" den Gold Award des Deutschen Design Clubs erhalten. Forschende der TU Chemnitz und des Fraunhofer ENAS haben mit ihren Ultraschallwandlern die Machbarkeitsanalyse für die Ultraschallpflaster zur kontinuierlichen medizinischen Überwachung unterstützt.Read moreThere is even more. Read all the research news.